Beer Manufacture

Brewing beer is an ancient art that has increasingly fallen into oblivion. Although more beer is produced on earth than ever before, these are computer-controlled products. The computer has replaced humans as brewmasters. Even in microbreweries, sensors and programs are taking over the work that the brewmaster used to do with his own senses and hands.

We taught ourselves the craft of brewing. We had to work overtime and work in the vat with the mixing ladle ourselves until a really good beer was produced. The first brews were cooked in the cauldron in the kitchen and then tasted. This was followed by the first tests with our small system. The best techniques have been developed to process the ancient grains emmer and einkorn, which are more difficult than barley. An in-house yeast nursery has also been set up, so that we always have fresh yeast for brewing.

Of course, our beer is unpasteurized and unfiltered. Since our brewing is handmade, each brew is unique. Taste the individual brews! You are guaranteed to have a different taste experience every time.

Our emmer and einkorn comes from the Haschahof in Vienna Favoriten, where it is grown in organic farming. After that, it is malted and can then be consumed. Emmer and einkorn are ancient grains, whereby einkorn can be considered the forefather of all wheat and emmer is closely related to durum wheat. Both have a natural protective shell, a so-called husk, which has been bred away from today's high-performance varieties. They also contain more valuable protein, vitamins and minerals. This is also the secret of their strong, pithy taste, because the more of these ingredients they contain, the more intense the grain tastes.

In terms of brewing beer, emmer and einkorn have some special properties. For example, they contain less starch than the highly cultivated barley and wheat malts, but have a protein content five times higher. The husks are much larger. Due to the low starch content, less high original gravities can be achieved with ancient grains. This is a disadvantage if you aim for the highest possible alcohol content. However, we are of the opinion that it is not the alcohol content that is decisive, but whether the beer tastes good! And here the originality, which goes hand in hand with the high protein content, is a great advantage. Unlike barley, emmer and einkorn husks do not give off bitter notes. On the other hand, with their high protein content, they provide a very complex, full-bodied malt body. And also for a nice head of foam on the beer, a lot of protein is favorable. But there are also differences between the ancient grain malts. This way, emmer provides a slightly slimmer malt body and a subtle, fruity acidity. Einkorn is full-bodied and pithy.

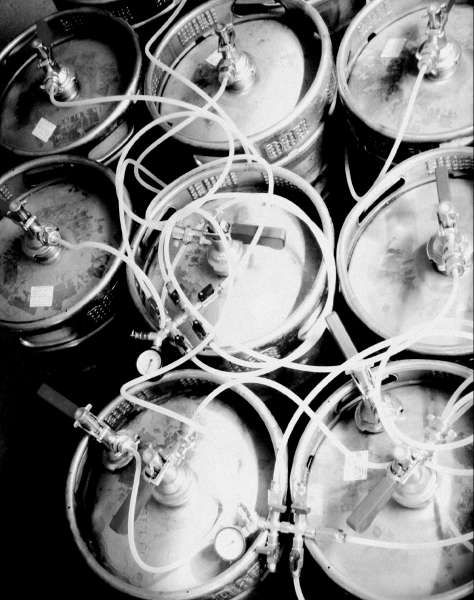

The brewing process itself takes place in several steps. First, the malt is crushed and mixed with hot water. The starch in the malt is already being converted into sugar, which is caused by the enzymes. Once all the starch has been converted into fermentable sugar, lautering follows. The sugary wort is separated from the husks, the grain husks, and other grain residues. The wort is boiled and hops are added, which give off its bitterness to the wort at these high temperatures. The wort is then cooled, yeast is added and pumped into the fermentation tank. This is followed by fermentation into the finished beer, which takes place gently and over several weeks in our house. This way, aromas of the young beer are preserved that would otherwise be blown out. Finally, at a cool temperature, the fermentation's own carbonic acid is bound in the beer – similar to champagne production. The beer is constantly tasted by us and its taste development is observed. Only when the optimal ripening point has been reached, the WIENER BEER is ready for bottling!

Would you like to know more about our brewery? Then visit our

Wiener Bier Brauerei Führungen